How does laser marking work?

Laser is the abbreviation for "Light Amplification by Stimulated Emission of Radiation". In order to understand how it works, one should first look at the structure of a laser.

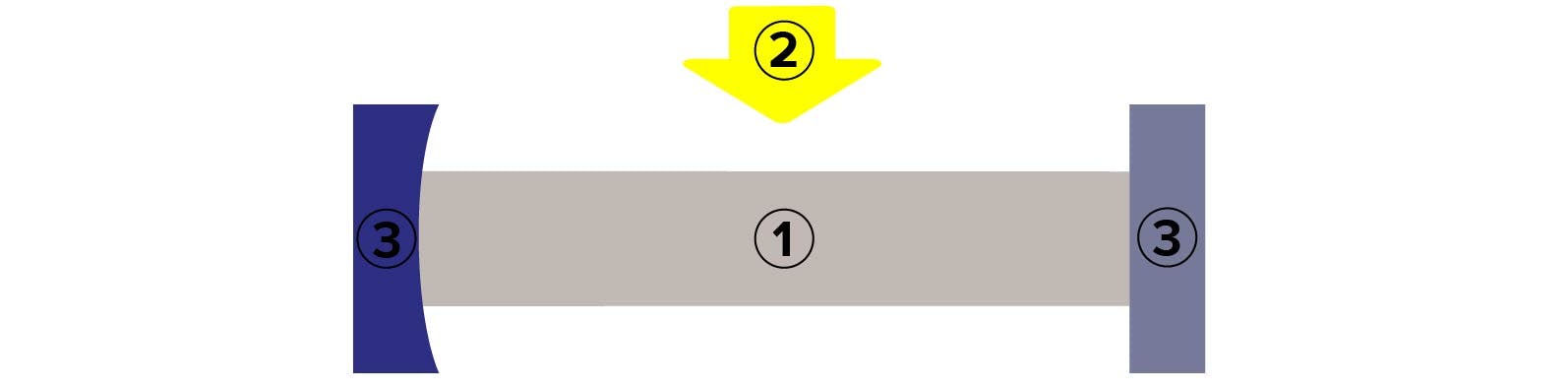

Basically, lasers consist of three components: the laser medium (solid, liquid, gaseous), a pump source and the resonator.

- Laser medium: This is used to generate the (laser) light by stimulated emission.

- Pump source: Excites the laser active medium, a population inversion is generated in the laser medium.

- Resonator: Essentially consists of 2 mirrors between which the light particles (photons) are reflected.

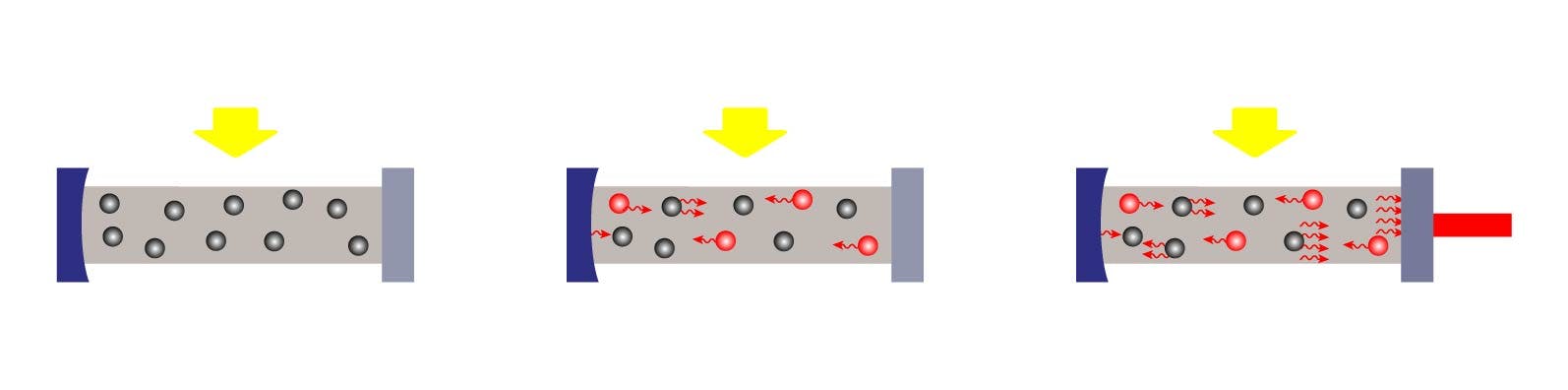

Electrons are brought to a higher energy level by the energy supplied by the pump source (optical pumping). Spontaneous emission causes light particles (photons) to be emitted, which are reflected back and forth between the two resonator mirrors. These generate more and more photons each time they pass through the laser medium again (stimulated emission). This process builds up like an avalanche, resulting in a concentrated beam of light. One of the mirrors is partially transparent and allows the light beam to escape - the actual laser beam.

When the laser beam hits a surface, it causes changes in the material. A distinction is made between material changes on the surface, below the surface or a coating removal (e.g. ink) from the surface. These depend on the laser marking process, which is largely dependent on the type of material to be engraved.